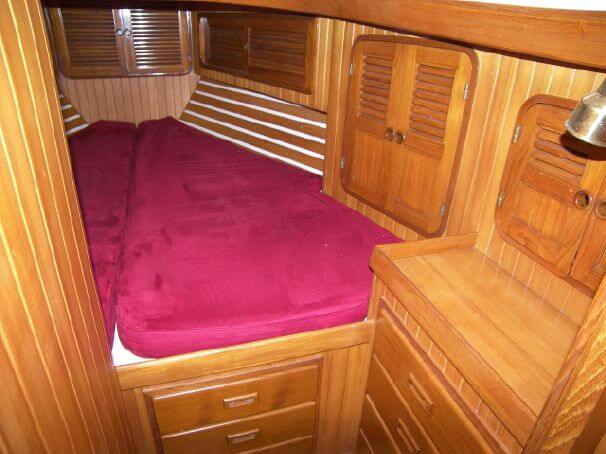

How many of you have woken up in a beautiful anchorage with a sore hip from your lousy, old v-berth cushions? Well, I am sick of it and have decided to do something about it – pronto. While Jeff could sleep on almost anything and not complain, I really want to be comfortable, especially since we plan to spend months, if not entire seasons, living aboard Bear.

We have plans to revamp our v-berth this winter with new cushions, fans, and LED lighting. We both enjoy reading in bed before drifting off to sleep, and these upgrades will surely make the experience more enjoyable. Our current configuration includes one fan, mounted on the port side bulkhead, which, in its current position, does not offer much breeze to the person on the starboard side of the bunk. While the lighting and fan issues need to be addressed while on the boat, the mattress issue can, and will be, addressed from afar.

I began researching foam a few weeks ago when I started the cockpit cushion project. I learned the differences between open cell, closed cell (floatation foam), and polyurethane vs. latex foams. I have since scoured the internet looking for advice on making v-berth cushions. One of the most interesting blog posts I found was from a couple that made their own v-berth cushions by cutting two twin mattresses to size. For this handy couple, this method was a cheap alternative to purchasing a custom innerspring mattress.

I must admit, I like the idea of having a “real” mattress on the boat. It seems like a simple, but surefire way to make our time aboard Bear seem less like camping (which, I should say, I like in small doses, but not for an extended period).

While we are usually more than happy to go the DIY route, we have a long list of jobs that need to be completed before we splash Bear in the spring. With this in mind, Jeff and I decided to visit the local mattress factory to see if they could do the job, and, more importantly, what it would cost.

We met with Matt at Verlo Mattress Factory on a rather quiet night at the store. With no one else looking for answers to slumber comfort, we were able to spend the better part of an hour discussing the needs for our floating home. We began by unrolling the cushion covers to our now defunct v-berth cushions and taking some measurements. With these in hand, Matt showed us a selection of foam mattress materials. He described how we could layer foams to create the depth and density we desired. As he talked about the options, I realized how easily we could make a foam mattress ourselves and became eager to see how his price would compare to a DIY version.

After he showed us all of the foam options, we asked whether he could create a custom innerspring mattress. With some reluctance, he said that he thought that they could, but it would be very expensive. Knowing that Jeff was pondering the same question as me, I prodded him a bit for the “expensive” price. When he came up with a figure that was well under $1000, we both pressed him for details on making a custom innerspring. Seeing our slightly geeky, albeit genuine enthusiasm for this option, Matt took us into the back room to view the inner spring coils and to discuss the challenges to making mattresses that would fit the odd shape of our v-berth. Armed with the knowledge of the cruisers who I mentioned above who reconstructed twin mattresses, I knew that it was possible, even if it was not something that Verlo would want to do.

About the whole versus thing, there are hybrid mattresses and not all of them only have the respective drawbacks of foam and springs. Although, truth to be told, there’s not too many of them, innerspring & memory foam that is.